The Parker Hydraulic Pump plays a crucial role in enhancing productivity across various industries. With its unmatched power and reliability, this hydraulic pump has become a trusted solution for numerous applications. Designed to deliver exceptional performance, it ensures optimal fluid transfer and motion control. The Parker Hydraulic Pump’s robust construction and cutting-edge technology make it a preferred choice for industries that prioritize efficiency and precision. In this comprehensive overview, we will explore the fundamental features and advantages of the Parker Hydraulic Pump, highlighting its significance in maximizing productivity.

Overview of Parker Hydraulic Pump

The Parker Hydraulic Pump is a highly regarded hydraulic solution known for its exceptional performance and reliability. It encompasses a range of fundamental features and components that set it apart in the industry. This pump plays a vital role in various industries and applications, providing efficient fluid transfer and precise motion control.

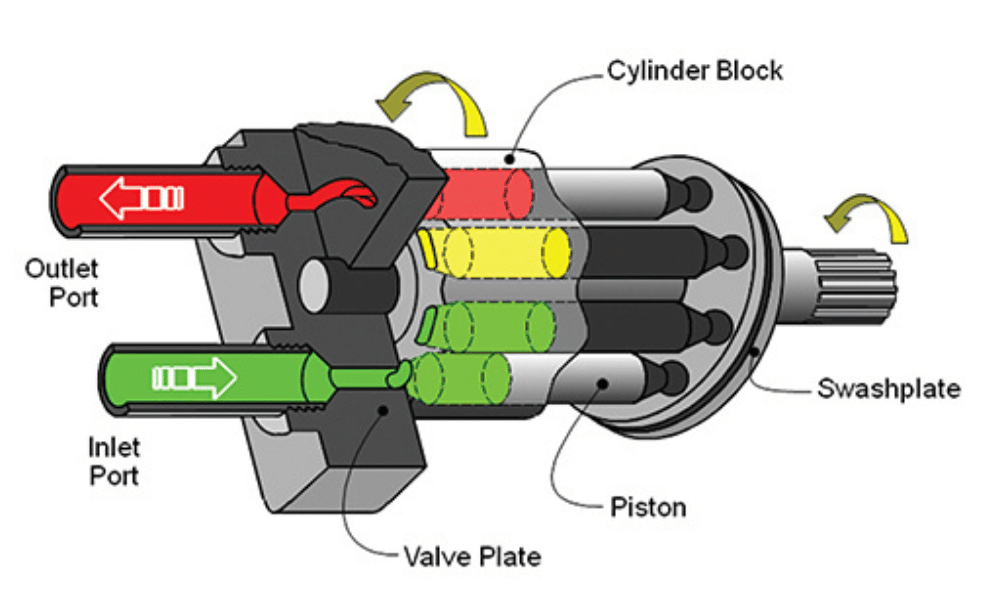

At its core, the Parker Hydraulic Pump converts mechanical power into hydraulic energy, enabling the smooth and controlled movement of fluids. It boasts robust construction and high-quality materials, ensuring durability and longevity even in demanding environments.

The versatility of the Parker Hydraulic Pump is evident in its widespread applications across industries such as manufacturing, construction, mining, and more. It powers machinery and equipment, facilitating precise control in tasks ranging from lifting heavy loads to powering hydraulic systems.

With its advanced design and engineering, the Parker Hydraulic Pump delivers reliable performance under varying operating conditions. It operates efficiently, minimizing energy consumption and maximizing productivity. Whether it’s providing power for industrial machinery or enhancing the performance of hydraulic systems, the Parker Hydraulic Pump excels in meeting the diverse needs of different applications.

In summary, the Parker Hydraulic Pump stands as a trusted hydraulic solution known for its performance and reliability. Its broad range of applications and fundamental features make it an invaluable component in industries that require efficient fluid transfer and precise motion control.

Advantages of Parker Hydraulic Pump

The Parker Hydraulic Pump offers a host of advantages that make it a preferred choice in the industry. Its superior power, performance, and reliability set it apart from other hydraulic pumps. Here are some key advantages of the Parker Hydraulic Pump:

- Superior Power and Performance: The Parker Hydraulic Pump is designed to deliver exceptional power and performance, ensuring efficient fluid transfer and precise motion control. It provides the necessary force and pressure to handle demanding applications, enabling smooth and reliable operation.

- Handling Heavy Loads: This pump excels in handling heavy loads with ease. Its robust construction and advanced design enable it to withstand high pressures and efficiently transfer fluids in applications that require substantial force and power.

- Reliable Operation: The Parker Hydraulic Pump offers reliable operation, ensuring uninterrupted performance in critical applications. It is built with high-quality materials and components, ensuring durability and minimizing the risk of breakdowns or system failures.

- Durability and Longevity: With its rugged construction and high-quality components, the Parker Hydraulic Pump is built to last. It can withstand harsh environments, extreme temperatures, and heavy-duty applications, ensuring long-lasting performance and minimizing downtime.

- Energy Efficiency: The pump is designed with energy efficiency in mind, minimizing power consumption without compromising performance. This not only helps reduce operational costs but also contributes to environmental sustainability.

- Smooth and Precise Control: The Parker Hydraulic Pump offers precise control over fluid transfer and motion, enabling operators to achieve accurate positioning and movement. This level of control enhances productivity and efficiency in various applications.

- Reduced Maintenance: Thanks to its reliable design and high-quality components, the Parker Hydraulic Pump requires minimal maintenance. This reduces downtime and maintenance costs, allowing for uninterrupted operation and increased productivity.

- Compatibility with Other Systems: The Parker Hydraulic Pump is designed to integrate seamlessly with other hydraulic components and systems. This compatibility allows for easy installation and integration into existing systems, providing a hassle-free solution for hydraulic applications.

In conclusion, the Parker Hydraulic Pump offers numerous advantages, including superior power, reliable operation, durability, energy efficiency, smooth control, and compatibility with other systems. These advantages make it a preferred choice for industries seeking optimal hydraulic performance and productivity.

Cutting-edge Technology and Innovation

The Parker Hydraulic Pump incorporates cutting-edge technology and innovative features, making it a frontrunner in hydraulic pump technology. By embracing advancements in engineering, the pump offers enhanced performance, efficiency, and control. Here are some key technological features and innovations found in the Parker Hydraulic Pump:

- Intelligent Control Systems: The pump integrates intelligent control systems that optimize performance and efficiency. These systems use advanced algorithms and sensors to monitor and adjust parameters in real-time, ensuring precise fluid transfer and motion control.

- Energy-efficient Design: The Parker Hydraulic Pump incorporates energy-saving features and designs that minimize power consumption. This includes variable displacement technology, load-sensing capabilities, and efficient hydraulic circuitry, resulting in reduced energy waste and operational costs.

- Advanced Materials and Manufacturing: The pump utilizes advanced materials and manufacturing techniques to improve performance and durability. Innovative materials, such as high-strength alloys and composite components, enhance reliability and extend the pump’s lifespan.

- Intelligent Diagnostics and Predictive Maintenance: The pump is equipped with intelligent diagnostics systems that monitor its condition and performance. Through data analysis and predictive algorithms, potential issues can be identified in advance, allowing for proactive maintenance and minimizing downtime.

- Compact and Space-saving Designs: Parker continually innovates the size and footprint of their hydraulic pumps. Compact and space-saving designs enable easy integration into tight spaces and equipment, making them suitable for applications with limited installation areas.

- Advanced Hydraulic Circuitry: The Parker Hydraulic Pump incorporates advanced hydraulic circuitry, optimizing the flow of fluid and enhancing system performance. This includes proportional control valves, pressure compensation, and flow control technologies that ensure precise control and efficient operation.

- Smart Connectivity and Remote Monitoring: The pump integrates smart connectivity features, allowing for remote monitoring and control. With IoT-enabled capabilities, operators can remotely access pump performance data, troubleshoot issues, and make adjustments from anywhere, improving operational efficiency.

These cutting-edge technologies and innovations incorporated into the Parker Hydraulic Pump contribute to improved precision, efficiency, and performance. By staying at the forefront of hydraulic pump technology, Parker ensures that their pumps meet the evolving needs of industries and deliver optimal results in diverse applications.

Wide Range of Models and Configurations

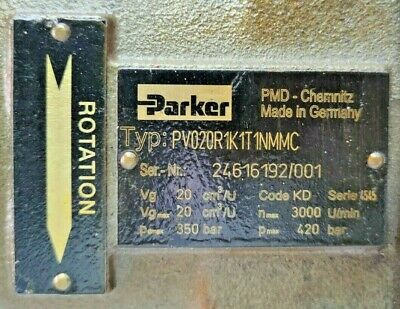

The Parker Hydraulic Pump offers a wide range of models and configurations to suit various application requirements. This versatility allows users to select the most suitable pump for their specific needs. Here are some key aspects of the wide range of models and configurations available:

- Model Variations: The Parker Hydraulic Pump is available in different models, each tailored to accommodate specific flow rates, pressures, and system sizes. This ensures that there is a pump suitable for both small-scale applications and large-scale industrial systems.

- Flow Capacities: The pump models offer a range of flow capacities to meet different fluid transfer requirements. Whether it’s a low-flow application or a high-flow demand, Parker provides pumps with the appropriate flow capacity for efficient operation.

- Pressure Ratings: The Parker Hydraulic Pump is designed to handle different pressure ranges. From low-pressure systems to high-pressure applications, there are pump configurations available to suit the specific requirements of each application.

- Mounting Options: Parker Hydraulic Pump provides a variety of mounting options to accommodate diverse installation needs. Whether it’s a compact design for space-constrained environments or a specific mounting orientation requirement, Parker offers suitable options.

- Customization Options: In addition to the standard models and configurations, Parker offers customization options to meet specific application needs. This includes modifications such as port configurations, shaft options, and material choices, ensuring the pump is optimized for its intended use.

- Adaptability to Different Industries: The Parker Hydraulic Pump is versatile and adaptable, making it suitable for a wide range of industries. Whether it’s manufacturing, construction, agriculture, or any other sector, Parker provides models and configurations that align with the unique demands of each industry.

- Compatibility with Accessories: The Parker Hydraulic Pump is designed to work seamlessly with a variety of compatible accessories and components. This allows users to integrate additional features such as filters, valves, and sensors, further enhancing the functionality and performance of their hydraulic systems.

The wide range of models and configurations offered by the Parker Hydraulic Pump demonstrates its versatility and adaptability to meet diverse application needs. Whether it’s selecting a standard model or customizing a pump to specific requirements, Parker ensures that the hydraulic system is optimized for efficient fluid transfer and motion control.

Industry Applications

The Parker Hydraulic Pump finds extensive application in various industries, playing a crucial role in enhancing productivity and efficiency. Here are some examples of industries where the Parker Hydraulic Pump is commonly used:

- Manufacturing: In the manufacturing industry, the Parker Hydraulic Pump powers machinery and equipment, enabling precise control and movement. It is employed in applications such as machine tools, material handling equipment, and assembly lines, contributing to efficient production processes.

- Construction: The construction industry relies on the Parker Hydraulic Pump for a wide range of applications. It powers hydraulic systems in construction machinery such as excavators, loaders, cranes, and concrete pumps. The pump provides the necessary force and control for tasks like digging, lifting, and material placement, enhancing construction efficiency and productivity.

- Mining: The mining industry extensively utilizes the Parker Hydraulic Pump for various applications. It powers hydraulic systems in mining equipment like excavators, loaders, and rock drills. The pump plays a vital role in tasks such as digging, hauling, and processing minerals, contributing to efficient mining operations.

- Agriculture: In the agricultural sector, the Parker Hydraulic Pump is essential for powering farm machinery and equipment. It enables precise control in applications such as tractors, harvesters, irrigation systems, and implements. The pump contributes to tasks like plowing, planting, harvesting, and irrigation, enhancing agricultural productivity.

- Material Handling: The Parker Hydraulic Pump is widely employed in material handling equipment, including forklifts, cranes, and conveyor systems. It enables smooth and controlled movement, lifting, and positioning of heavy loads, facilitating efficient warehouse operations and logistics.

- Automotive: Within the automotive industry, the Parker Hydraulic Pump is utilized in power steering systems. It provides the necessary hydraulic pressure to assist in steering control, enhancing driver comfort and maneuverability. The pump ensures smooth and responsive steering, contributing to safe and enjoyable driving experiences.

- Marine: In the marine industry, the Parker Hydraulic Pump powers various systems onboard ships and boats. It is employed in propulsion systems, steering mechanisms, and cargo handling equipment. The pump provides reliable power and control, ensuring safe navigation and efficient cargo operations.

These examples highlight the wide-ranging applications of the Parker Hydraulic Pump across diverse industries. Its reliability, precision, and performance make it a crucial component in enhancing productivity and operational efficiency in various sectors.

Reliable Support and Service

Parker understands the importance of providing reliable support and service to customers using their Hydraulic Pump. With a commitment to customer satisfaction, they offer comprehensive assistance to ensure smooth operation and maintenance of the pump. Here are some key aspects of the support and service provided by Parker:

- Expert Technical Assistance: Parker has a team of knowledgeable professionals who are readily available to provide expert technical assistance. They offer guidance on pump selection, installation, troubleshooting, and system optimization. Their expertise ensures that customers receive the right support and solutions for their specific needs.

- Customer Care: Parker values customer satisfaction and has a dedicated customer care team that is committed to addressing customer inquiries and concerns promptly. They provide assistance with product information, order processing, and general queries, ensuring a positive customer experience.

- Maintenance Programs: Parker offers maintenance programs tailored to the needs of customers. These programs include scheduled maintenance, inspections, and preventive services to ensure the optimal performance and longevity of the Hydraulic Pump. By following a proactive maintenance approach, customers can minimize downtime and maximize the pump’s reliability.

- Spare Parts Availability: Parker understands the importance of having readily available spare parts for maintenance and repairs. They ensure the availability of genuine spare parts for their Hydraulic Pump, allowing customers to easily obtain the necessary components to keep their systems running smoothly.

- Training and Education: Parker provides training programs and educational resources to empower customers with knowledge and skills related to their Hydraulic Pump. These programs cover topics such as pump operation, maintenance best practices, and safety guidelines. By equipping customers with the right knowledge, Parker promotes safe and efficient pump operation.

- Global Network: With a global presence, Parker has an extensive network of authorized distributors, dealers, and service centers. This network ensures that customers can access support, service, and spare parts locally, regardless of their location. It allows for convenient and timely assistance when needed.

- Expertise in Hydraulic Systems: Parker has a wealth of experience and expertise in hydraulic systems, making them a trusted partner for customers. They understand the intricacies of hydraulic technology and can provide tailored solutions based on specific requirements. Their in-depth knowledge ensures that customers receive reliable support and service.

In conclusion, Parker’s reliable support and service offerings reaffirm their commitment to customer satisfaction and the optimal performance of their Hydraulic Pump. Through expert technical assistance, customer care, maintenance programs, spare parts availability, training, and a global network, Parker ensures that customers receive the necessary support to keep their hydraulic systems operating efficiently.

Conclusion

In conclusion, the Parker Hydraulic Pump is a trusted and reliable solution that offers unmatched power and reliability. It plays a pivotal role in enhancing productivity across various industries, providing efficient fluid transfer and precise motion control.

With its cutting-edge technology, the Parker Hydraulic Pump delivers exceptional performance and efficiency. The wide range of models and configurations available ensures that customers can choose the pump that best suits their specific requirements. Its durability and longevity guarantee reliable operation, minimizing downtime and maintenance costs.

Parker’s commitment to innovation is evident in the advanced features incorporated into the Hydraulic Pump. From intelligent control systems to energy-efficient designs, these innovations contribute to maximizing productivity and reducing operational costs.

Moreover, Parker’s comprehensive support and service further enhance the customer experience. Expert technical assistance, maintenance programs, and readily available spare parts ensure the smooth operation and longevity of the Hydraulic Pump.

In summary, the Parker Hydraulic Pump is a leading choice for industries seeking optimal fluid transfer and motion control. Its unmatched power, reliability, and customer-oriented support make it an invaluable asset for enhancing productivity. Parker’s commitment to excellence solidifies their reputation as a trusted hydraulic pump solution.

Related Keywords

# parker hydraulic pump,

# parker hydraulic pump,

# hydraulic pump parker,

# parker pump,

# parker hydraulic motors,

# hydraulic motors parker,

# hydraulic pump catalog,